How it Works . . .

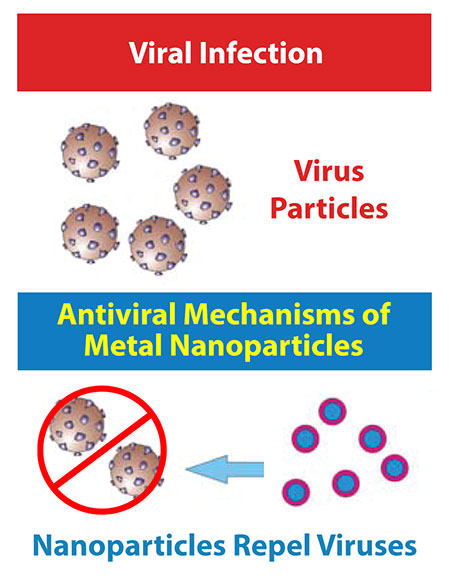

Viruses can only replicate inside a living cell; outside the cell, they’re on a path to either infect us, or their own destruction. How long a virus survives outside a cell varies. Research suggests it lives for up to 72 hours on hard, shiny surfaces.

Silver ion inhibits the process of cell division by which the microbial replicates. The action of silver additive is based on the slow and continuous leaching of super fine silver ions that interact with the metabolism of the microorganisms in various ways. Moisture in the air accelerates the property of ion exchange process by which silver is released at a continuous rate and maintaining an antimicrobial surface. In presence of moisture the silver ions create an exchange for sodium ions from the environment. As the environment becomes more humid, microbial growth would be more, the Antimicrobial Panel discharges more silver ions thereby long-term protection is ensured.

Antimicrobial action of silver comes from the chemical properties of its ionized form Ag+. When microbes, encounter an antimicrobial treated coatings surface, Ag+ is released accordingly to the surface of the treated product to inhibit the microbial growth.

Antimicrobial action of silver comes from the chemical properties of its ionized form Ag+. When microbes, encounter an antimicrobial treated coatings surface, Ag+ is released accordingly to the surface of the treated product to inhibit the microbial growth.

Antimicrobial Panels rely on a Silver Ion Agent

Silver ion agent has been selected for the following reasons:

a. Microbial r 99.9%

b. Environmental compatibility/ compliance

c. Thermal stability

d. Effective life expectancy

e. It can be used for both indoor & outdoor applications

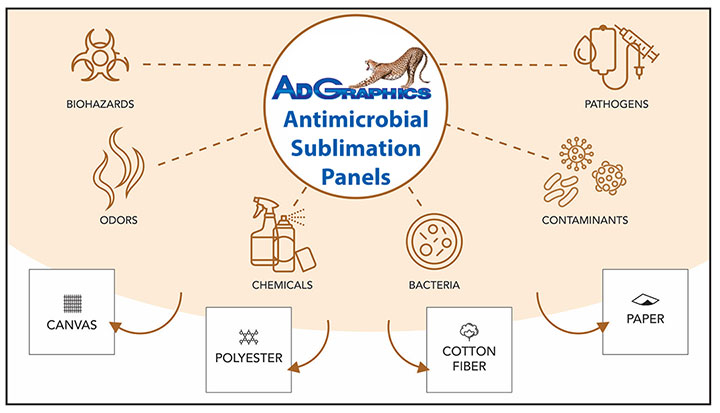

OUR COATINGS ARE PERFECT FOR THE MOST STRINGENT OF SAFETY REQUIREMENTS

Our proprietary coatings utilized on all AdGraphics’ print media provide a surface that is resistant to all forms of chemicals, bacteria*, contaminants, and pathogens. Due to the smooth surface of our coatings, AdGraphics’ panels can be easily and thoroughly cleaned with a variety of cleaners and chemicals unlike other print media such canvas, paper, and powder coated panels.

As a result of the cross-linked nature of our proprietary coating, all AdGraphics’ print media have the absence of open and closed pores. All of our products provide a protection equivalent to a closed cell surface which offers unmatched chemical and stain resistance as demanded by the most stringent of safety requirements.

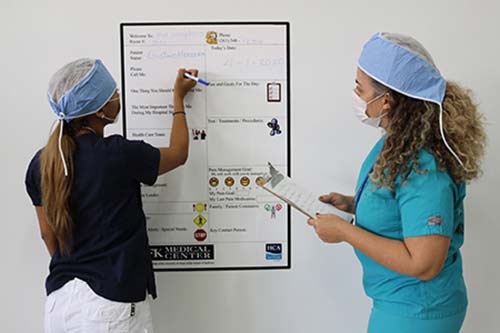

AdGraphics’ print media is ideal and suitable for environments that demand the utmost hygienic, clean-ability, and safety requirements possible to ensure a safe environment for all who may come into the vicinity or contact with our print media.

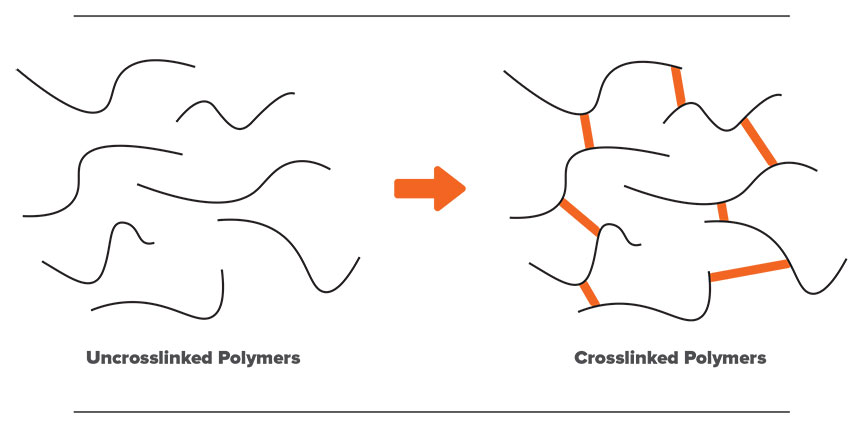

WHAT DOES “CROSS-LINKED” MEAN?

As mentioned, AdGraphics’ panels are coated with a cross-linked coating. But what exactly does this mean? The chemical process that links polymer chains together is known as cross-linking. Prior to the completed production of a AdGraphics panel, the polymers of the AdGraphics coating are unlinked and move about freely in the coating. To make this a bit easier to understand, think about strands of pasta in a pot. Imagine each strand as a polymer. Each strand of pasta can be individually pulled out of the pot. Cross-linking causes a chemical reaction that links the polymers together. In the case of the strands of pasta, they are all now connected and can all be pulled out of the pot together at once instead of individually. As the coated panels travel down our coating line, they reach a point in our proprietary process where a chemical reaction causes the polymers of the coating to join together; this is known as cross-linking. As all the polymer strings are joined together end-to-end, they form one long and stable polymer string.

The 100% cross-linked polymers in the final product are what allow us to produce a product that has phenomenal durability, scratch resistance, chemical and stain resistance, color retention, fade resistance and more.

Additionally, this cross-linked coating is also what makes AdGraphics’ panels able to be cleaned with a vast variety of cleaners without affecting the sublimated image.